On October 1 1931 at 1:16pm, the first Ford vehicle made in Dagenham rolled off the production line. Ninety years later, nearly 11 million cars, trucks and tractors have been built at the site in East London.

On October 1 1931 at 1:16pm, the first Ford vehicle made in Dagenham rolled off the production line. Ninety years later, nearly 11 million cars, trucks and tractors have been built at the site in East London.

Today, Dagenham produces and exports around a million diesel engines a year. Its future was secured by a deal to supply engines for the new Ford Transit and Volkswagen Transporter vans, which will be assembled in Turkey from 2023.

To celebrate the factory’s 90th anniversary, we take a brief look at its story so far.

Prefect makes a million

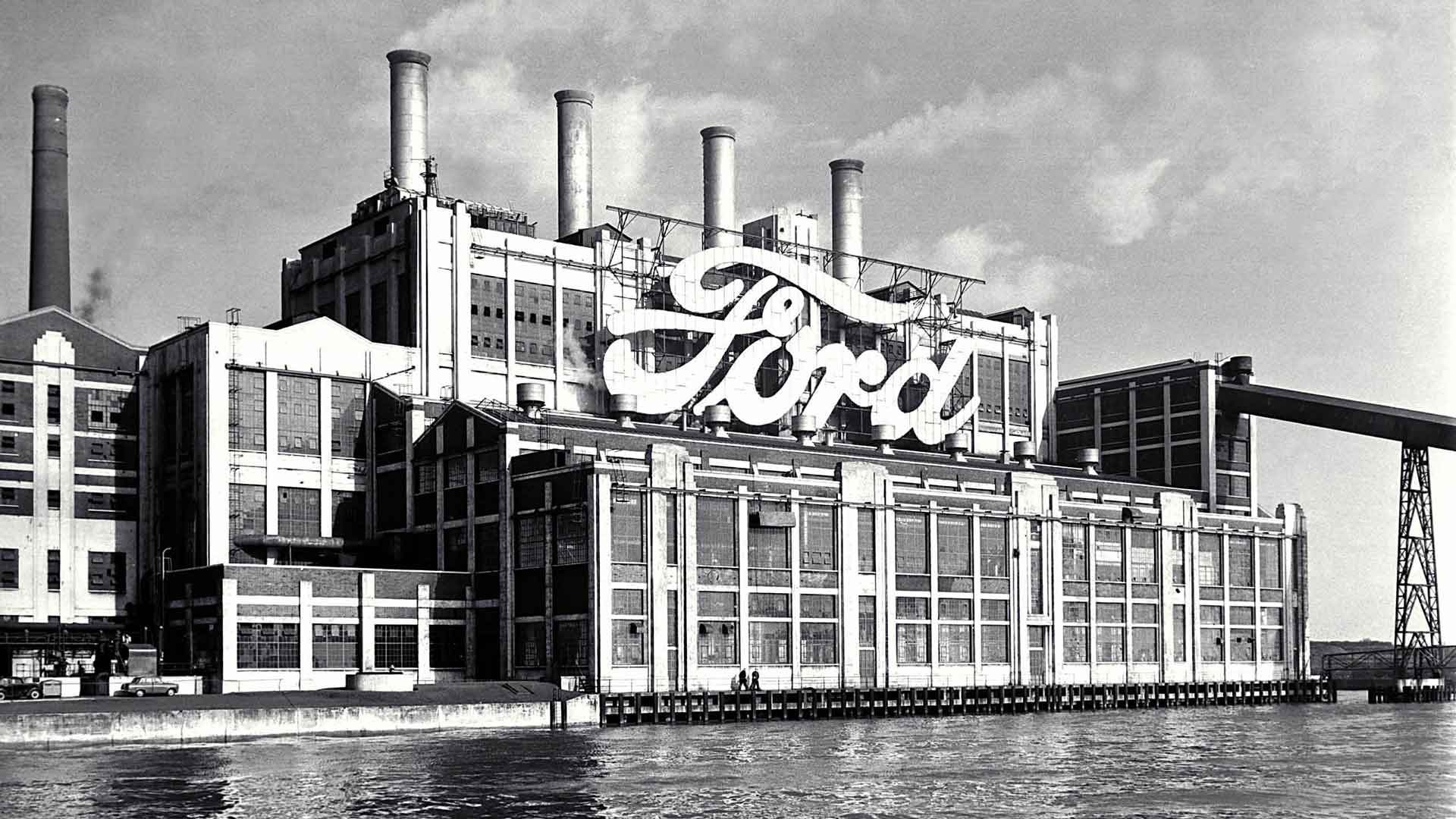

Dagenham was a huge operation from the start; the site had its own steel foundry, power station and on-site railway. Construction took two years and vast quantities of concrete – essential to support the foundations on soggy marshland.

That first vehicle off the production line was a Ford AA truck, based on the successor to the legendary Model T. However within less than a decade, Dagenham would become part of the war effort, building engines and armoured vehicles.

Normal service was swiftly resumed once World War Two ended, and the factory built its millionth car – a 10hp Prefect – in 1946. Famously, it was priced at exactly £100.

Industrial action

The factory expanded hugely in the 1950s, producing popular cars such as the Anglia and Zephyr. The all-conquering Ford Cortina was also built in Dagenham from 1962, with the millionth diesel engine following in 1965.

However, it wasn’t all plain sailing. In 1968, Ford’s female sewing machinists went on strike, demanding the same hourly wage as their male colleagues. With no car seat covers being made, car production at Dagenham ground to a halt.

After three weeks, the strike was resolved, the workers’ action leading to the Equal Pay Act of 1970. It also inspired Made in Dagenham, the West-End musical and film starring Sally Hawkins and Bob Hoskins.

The engine of change

By the 1970s, the plant looked dated and more industrial strife (not unique to Ford) was taking its toll. The company decided to build its new Escort in Saarlouis, Germany, while production of the Ford Fiesta was shared with a new site in Valencia, Spain.

Likewise, the 1982 Sierra was jointly produced with the Genk facility in Belgium, and by the 1990s only the Fiesta (and its Mazda 121 cousin) we being made in Dagenham.

The final Fiesta rolled off the line in 2002, leaving Dagenham as purely an engine plant, a role in which – despite large areas of the original site falling into disuse – it has thrived.

Ninety not out

In recent times, Dagenham joined the effort to make ventilators for the NHS for Covid patients. Ford transformed an empty warehouse into a manufacturing facility in just three weeks, then staffed it with up to five hundred people a day.

The Ford plant also played an important role in industrialising the production process of ventilators, so they could be made in large numbers. This echoed Henry Ford’s pioneering of mass production techniques in 1908 with the original Model T.

Another new facility at Dagenham will convert and customise Ford’s sporty MS-RT vans on-site. The factory may no longer build cars, but it has a place in British history – and a promising future.

ALSO READ:

Ford fan spends £77,000 on his dream Transit

The Ford GT and GT40 story

The amazing Ford Fiesta concepts they canned

[…] Granada that had gone before. However, people were better prepared for the shock of the Blue Oval’s new, the jarring arrival of the Sierra three years earlier thoroughly softening their […]