More than 60 companies have responded to the government’s request to help produce 20,000 ventilators to treat coronavirus patients. Vauxhall is the latest company to step up, with Jaguar Land Rover and Rolls-Royce also saying they will provide support.

Vauxhall has offered to help with 3D printing and the production of the crucial devices. The car company, which is now owned by the French automotive giant PSA, will work from technical drawings and blueprints provided by the government.

The Department of Health says that the NHS could require up to 20,000 additional ventilators. It currently has 5,000 adult ventilators and 900 for children.

Calling all manufacturers who can support our National Effort for #coronavirus ventilator production – to help, contact Government Business Support team: 0300 456 3565 / ventilator.support@beis.gov.uk

— Matt Hancock (@MattHancock) March 16, 2020

Vauxhall’s Ellesmere Port factory is one of a number of PSA’s European plants that has closed due to the coronavirus. Ellesmere Port is likely to remain closed until 27 March at the earliest.

In a statement, the company said: “Due to the acceleration observed in recent days of serious COVID-19 cases close to certain production sites, supply disruptions from major suppliers, as well as the sudden decline in the automobile markets, the chairman of the executive board with the members of the crisis unit, decided the principle of the closure of the vehicle production sites, according to the following schedule and until March 27.”

Vauxhall’s Luton plant, which is home to the Vivaro van, is scheduled to close tomorrow (19 March).

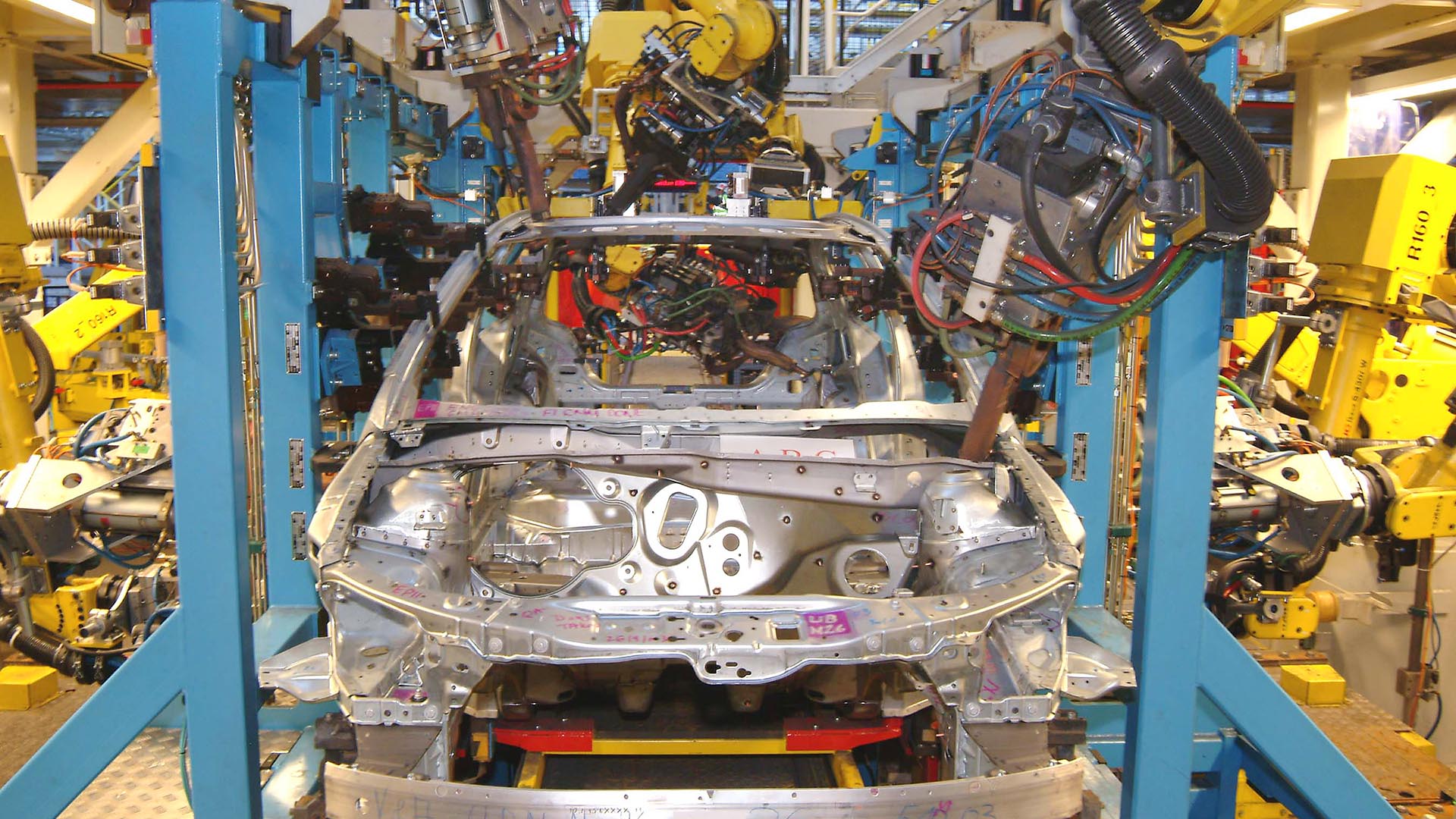

The closure of the Ellesmere Port factory will free up capacity to make ventilators.

‘Experts at assembly’

Helen Foord, head of government relations at Vauxhall, told The Guardian: “We are experts at assembly and efficient mass production; we know how to process and we know how to make it lean.

“We’ve offered our services as an assembly plant and we have 3D-printing capability at Ellesmere Port, too.”

David Bailey, a professor of business economics at Birmingham University, warned that it could take time for car manufacturers to be in a position to build the ventilators. He said: “What’s most likely is that if there’s a manufacturer already making ventilators that wants to work 24/7, other manufacturers could help in terms of staff, components and supply chains, supporting them in that way.

“Technicians could be redeployed to operate machinery on different production lines where there are similar manufacturing processes in place.

“Longer-term it might be about production lines but it would take a while to tool up. The issues will be supply chains. Where are these components coming from and if there is disruption, can they be purchased locally instead?”