Radical new British-designed battery technology could see dramatic reductions in charging times for electric cars.

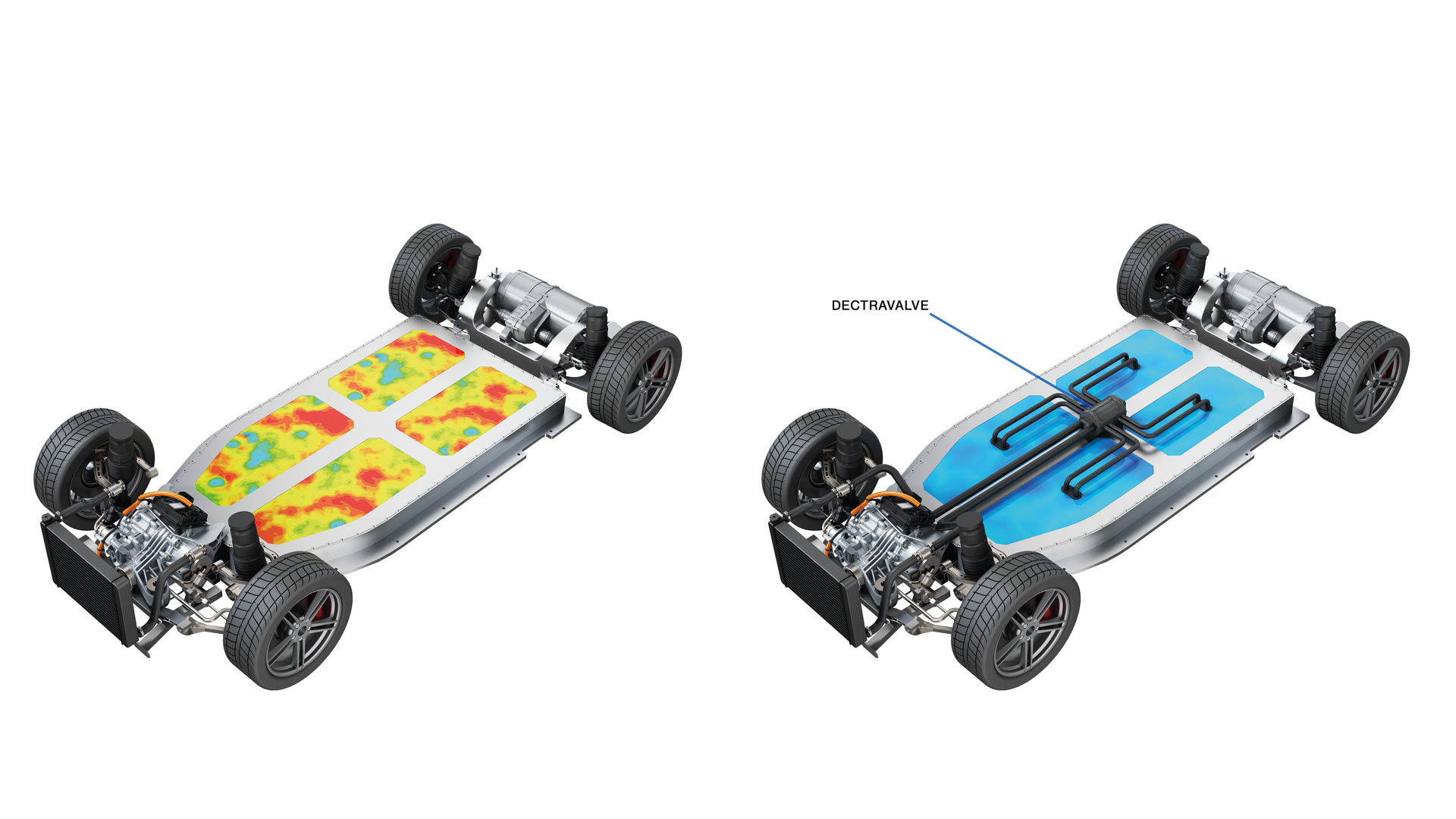

Nottingham-based company Hydrohertz has developed the new ‘Dectravalve’. The innovation is designed to regulate EV battery temperature, keeping the cells cooler.

Current electric car technology means fast charging can increase battery temperature to 56°C. Once above 50°C, chargers have to reduce their speed to avoid damaging the battery. This inevitably results in longer charging times.

However, in testing, the Dectravalve kept battery cells to a maximum of 44.5°C. It also ensured a smaller variation in temperature across the battery pack.

Longer range, shorter charging times

By keeping every cell below 50°C, and with no thermal hotspots across the pack, a Dectravalve-equipped battery can maintain peak charging performance.

Hydrohertz tests demonstrated that charging times for electric car batteries could be reduced by 68 percent.

When connected to a 350kW fast charger, this means a 10 to 80 percent charge could require just 10 minutes instead of 30 minutes. As a result, recharging an electric car could be almost as quick as refuelling a petrol or diesel vehicle.

The Dectravalve also keeps EV battery cells cooler in all conditions, meaning driving efficiency is improved by up to 10 percent. Depending on the battery size and electric car in question, this could mean an extra 30 or 40 miles of range.

British battery innovation

Founded in 2020 by Martyn Talbot, Hydrohertz has received three consecutive nominations for the Earthshot Prize.

CTO Talbot explained: “The Dectravalve solves a fundamental problem of EV battery thermal management systems – how to achieve true independent zone control of temperature without the complexity, weight and energy waste of multiple valve arrays.”

Paul Arkesden, CEO of Hydrohertz, was previously senior vice president of engineering at Singer Vehicle Design. Prior to that, he worked as head of engineering at McLaren Automotive, where he led development of the powertrain in the P1 hypercar.

Arkesden commented: “The automotive industry has been waiting for battery technology to catch up with consumer expectations, but progress has been slow and expensive. A new chemistry can take a decade to develop and require billions in investment. What we’ve done is take a different approach – we’ve dramatically improved how existing batteries perform by perfecting the thermal management of them.”

ALSO READ:

McLaren W1 unwrapped: tech secrets of new hybrid hypercar

[…] New British-designed EV battery technology could see a dramatic reduction in charging times and in increase in range for electric vehicles. Nottingham-based company Hydrohertz has developed the new ‘Dectravalve’. The innovation is designed to regulate EV battery temperature, keeping the cells cooler, says Motoring Research. […]