-

Behind the scenes at Bentley

© BentleyVisiting any car factory is fascinating. It’s difficult to comprehend the sheer scale of the operation that even a relatively small car manufacturer runs unless you actually see it. You also pick up loads of interesting tidbits along the way. We were recently shown around the Bentley plant in Crewe, which combines traditional craftsmanship with modern technology like few other places on Earth. Here’s what we learned.

-

Bentley has actual flying bees

© BentleyBentley’s winged emblem is known as the Flying B, but there are actual bees – the stripey, buzzing kind – on the grounds of the Bentley factory. Six hundred thousand of them, in fact. The bees are there to pollinate the trees and flowers dotted around the 130-acre site. There are 10 hives in total, you’ll see five just the other side of the main gate on Pyms Lane. They’re busy bees as well, producing 1,000 jars of honey in 2022. It’s very good stuff, apparently. Some is given as gifts to VIP guests, while the rest is donated to local schools, hospitals and other worthy causes.

-

You can line your Bentley with stone

© BentleyBentleys are heavyweight cars, but filling the interior with stone is surely going a bit far? Not really, because the stone veneers that Bentley has recently added to its range of trim finishes are just 0.1mm thick. Delicately shaved from rock and adhered to a flexible backing, they’re easily shaped and very light. There are three to choose from, and we were particularly taken with the sparkling silvery-grey of Galaxy and the gorgeous red and brown tones of Copper. They’re a deeply cool alternative to the usual wood, metal and carbon fibre finishes, and wonderfully tactile as well. They’re not smothered in layers of lacquer, so you can really feel the texture. Incidentally, the stone veneers aren’t on the online configurator – we checked.

-

There are a LOT of stitches in the emblem

© BentleyA Bentley emblem stitched onto the seat headrests is one of the most popular options that customers choose. It’s about the same size as the badge on the front of the car, roughly five inches from tip to tip and two inches from top to bottom. It’s stitched directly onto the leather, which is then pieced together into the headrest cover. And there are a lot of stitches: no less than 4,771. It used to be 4,760, but an extra 11 stitches were recently added to improve the clarity of the image. The difference is imperceptible to all but the most highly trained eyes, but it shows the level of attention to detail that Bentley strives for. The automated sewing machines take a couple of minutes to complete the emblem, but they can stitch any design you load into them.

-

The walls are alive

© BentleyWhile we were at Bentley, there was work going on inside the on-site showroom. It turned out a living wall was being installed – effectively a vertical garden. Potted plants are mounted to a frame, an irrigation system at the top waters the plants, then water collects at the bottom and runs through a filter back to the top. The showroom living wall isn’t the only one on-site, there are plenty dotted all over the factory buildings, using plant pots made from recycled battery boxes. The plants breathe in carbon dioxide and breathe out oxygen, helping to improve air quality at Crewe.

-

Bentley car bodies aren’t made in Crewe

© BentleyBentley may be proudly British, but not everything is made on-site in Crewe. That includes the bodyshells, which come from a factory in Leipzig, Germany. Indeed, in nearly 80 years of carmaking at Pyms Lane, the only bodyshell made on-site was the 2010-2020 Mulsanne. Contractor Pressed Steel made saloon bodies for all Bentleys (and Rolls-Royces) built between 1946 to 1998, while the Arnage body was also shipped in from elsewhere. Two-door cars were usually built by coachbuilders like Park Ward or H.J. Mulliner. Body production moved to Germany when the 2003 Continental GT – the first all-new Bentley of the Volkswagen era – was launched.

-

The factory is powered by the sun

© BentleyIn part, at least. There are currently 31,500 solar panels on the Bentley site: 10,000 on open ground near the factory buildings and 21,500 on rooftops. The factory has already achieved carbon-neutral status, but more solar panels will be added in the coming years as Bentley ramps up its use of renewable energy. Rainwater harvesting tanks also provide much of the factory’s water supply. The amount of waste associated with the production of each car has been slashed from 400kg to less than 10kg in just a few years.

-

The Bentley emblem is asymmetrical

© BentleyThe two wings of Bentley’s iconic emblem look identical at first glance. Look closely, though, and you’ll see there is a different number of ‘feathers’ on each side. Right now, there are 11 feathers on the right-hand side and 10 on the left, plus seven on the bottom. The number of feathers has actually changed many times throughout Bentley’s history. There have been as many as 13 feathers on each side, and up to 10 on the bottom. The emblem has also been both symmetrical and asymmetrical. These revisions started in the very early days of the marque, when founder W.O. Bentley became concerned about unscrupulous types passing off fake Bentley cars. By changing the emblem every so often, he made it easier to tell a forgery from the real deal.

-

You can have a long walk around the assembly hall

© BentleyAll the components made at Pyms Lane and brought in from outside suppliers come together in the assembly hall. It’s vast, at one-third of a mile long. That’s nearly 1,600 feet, or more than 480 metres. There are multiple production lines for the Continental, Flying Spur and Bentayga, each one twisting and turning through the building. You could easily walk a few miles along, around, through and underneath them. The lines are full of the latest technology to make assembling the cars as easy and efficient as possible, but it’s still an intricate (and therefore relatively slow) process. It takes 19 hours to put together a Bentayga, for instance. Even so, a record 15,174 Bentleys rolled out of the factory gates in 2022.

-

You may own a piece of Bentley without realising it

© BentleyA lot of leather goes into a Bentley. Each hide used has an area of five square metres, and 10 of them make up the trim and upholstery of a Continental GT, while 14 go into a Bentayga. A computer algorithm lays out the individual pieces that are needed from each hide, then they’re cut by a laser. The algorithm is programmed to use each hide as efficiently as possible, but the process still generates a lot of waste leather. This is collected and sent to companies that use it to make items such as wallets and keyrings, which are not necessarily Bentley-branded. Bentley is the only car manufacturer accredited by the Leather Working Group, which sets out standards to ensure leather used in consumer goods is traceable and sustainable.

-

They still own W.O. Bentley’s company car

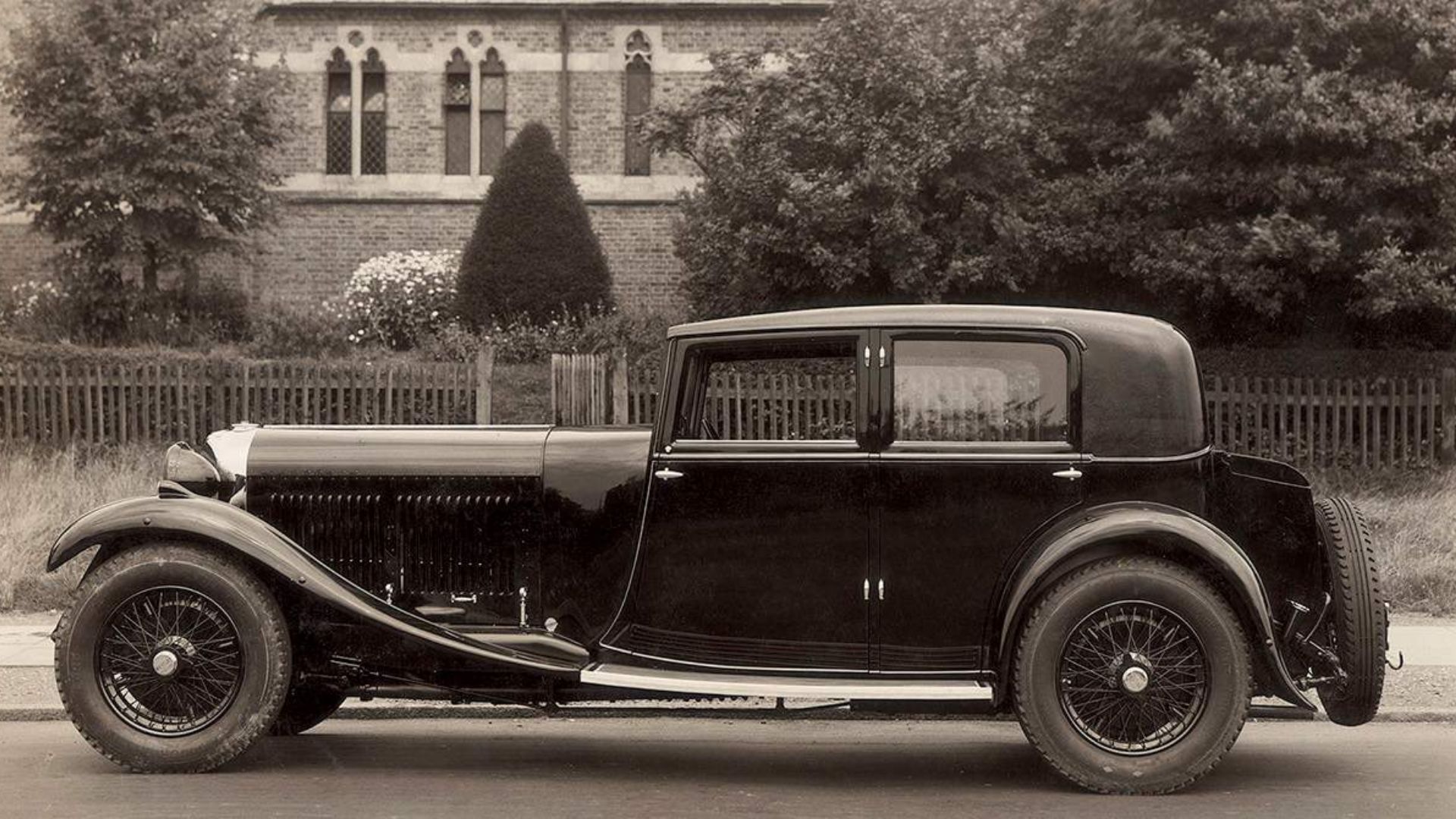

© BentleyWhen you own a car manufacturer, nobody will object if you nab the top-of-the-range model for your company car. Walter Owen Bentley did just that in 1930 when he took home an 8-Litre for his personal use. The 8-Litre was a bit of a monster, named after the size of its six-cylinder engine, which produced around 200-230bhp – a massive amount for the time. It was also a massive car, yet Autocar magazine recorded a top speed of 101mph, despite the 8-Litre being as aerodynamic as the building it was made in.

W.O.’s car was the second example built, with a short-wheelbase chassis and a saloon body by H.J. Mulliner. He kept it until 1932, when he was forced to give it up following Bentley’s acquisition by Rolls-Royce. The company finally bought the 8-Litre back in 2006. It has been sympathetically restored, looks incredible and goes like a train. We’re told it’s rather tricky to drive, though. Bentleys of this era have a central throttle pedal and a notoriously idiosyncratic gearbox that is very difficult to shift smoothly. But get it right and it’s immensely satisfying. Just don’t think about how much the car is worth…